OUR KNOW-HOW

Customised automation solutions

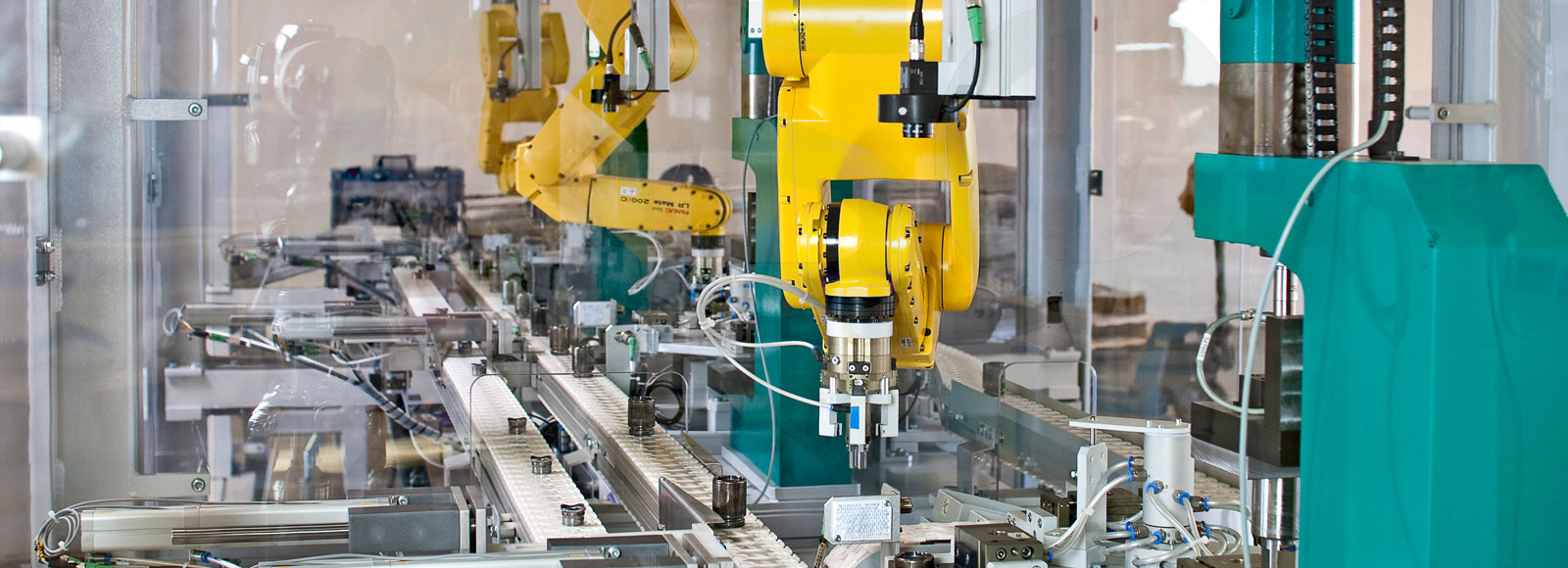

Based on your product and its characteristics, ASA AUTOMATION develops automation solutions that are precisely tailored to your requirements - turnkey, maximised and cost-optimised. Our team consisting of design, production, programming, assembly and service is already looking forward to solving your automation task.

Get to know us!

For us, every application, regardless of the product, is both a challenge and an opportunity for which we want to find a solution.

For us, every application, regardless of the product, is both a challenge and an opportunity for which we want to find a solution.

That is why ASA AUTOMATION offers automation technology for all industries.

Our main customers include national and international companies. These include companies from the automotive and supplier industry, the food industry, mechanical engineering and the chemical and pharmaceutical industries.

If consumers expect reliable function and quality from a product, then it is the car. With our many years of experience in the automotive and supplier industry,

If consumers expect reliable function and quality from a product, then it is the car.

With our many years of experience in the automotive and supplier industry, we use customised automation solutions to ensure that a wide variety of vehicle parts are manufactured to the required quality standards.

These can be, for example, systems for the assembly of brake pistons, for greasing windscreen wiper joint rods, for feeding housing parts or even fully automated drilling and deburring systems.

The more people come into contact with food, the greater the risk of contamination. The highest standards of hygiene are therefore essential in the food industry.

The more people come into contact with food, the greater the risk of contamination. The highest standards of hygiene are therefore essential in the food industry.

In addition, manufacturers must produce high-quality products in large quantities, react quickly to new products and product formats, maximise operating times and reduce costs at the same time.

All these market requirements can only be met through automation. It improves quality, efficiency, ergonomics and hygiene. Automation is no longer an advantage, but a necessity.

With customised concepts for pick and place applications (linear and robot-assisted), palletising and depalletising systems, conveyor systems and complete packaging lines, we have been helping our customers achieve their goals.

Many everyday items contain raw materials from chemical production. For example, detergents and cleaning agents, wall paints, cosmetics and much more.

Many everyday items contain raw materials from chemical production. For example, detergents and cleaning agents, wall paints, cosmetics and much more.

With its high demands on availability, flexibility, efficiency and safety, the chemical industry is one of the most complex branches of industry in terms of automation technology. And as the variety of products increases, so does the degree of automation in the industry.

Our expertise in the realisation of intelligent automation solutions for this industry is wide-ranging. These include, for example, filling systems, gluing and assembly systems, bag closing machines as well as Ki-assisted pick and place robot solutions.

Many medical devices have a direct impact on patients and harbour potentially high risks in terms of safety and treatment outcomes.

Many medical devices have a direct impact on patients and harbour potentially high risks in terms of safety and treatment outcomes.

For this reason, the manufacture of pharmaceutical products poses particular challenges for automation. Especially when cleanroom requirements also have to be met.

We know the industry and its requirements for a quality-assured and efficient production process and can support you with customised concepts.

These can be, for example, pick and place applications (linear and robot-assisted), palletising and depalletising systems, conveyor systems and packaging solutions.

PLANNING AND CONSULTING

At the beginning of a project, our sales specialists are your first point of contact. Together with you, they gather the basic information for the concept and quotation preparation as a basis for further planning.

Would you like to partially or fully automate your production? Or are you looking for new solutions to modernise, optimise or expand your existing automation?

Would you like to partially or fully automate your production? Or are you looking for new solutions to modernise, optimise or expand your existing automation?

Our sales team will assist you with all planning issues. They will work with you to develop your individual automation solution, customised to your requirements.

We start the process by asking specific questions to gain a comprehensive understanding of the challenge you present us with. We then develop the optimum concept for you and prepare a resulting budget offer.

Of course, we are also happy to support you with your retrofit tasks.

On request, we can create a 3D simulation during the planning phase to give you a better idea and to visualise movement sequences in the best possible way.

Project management and engineering

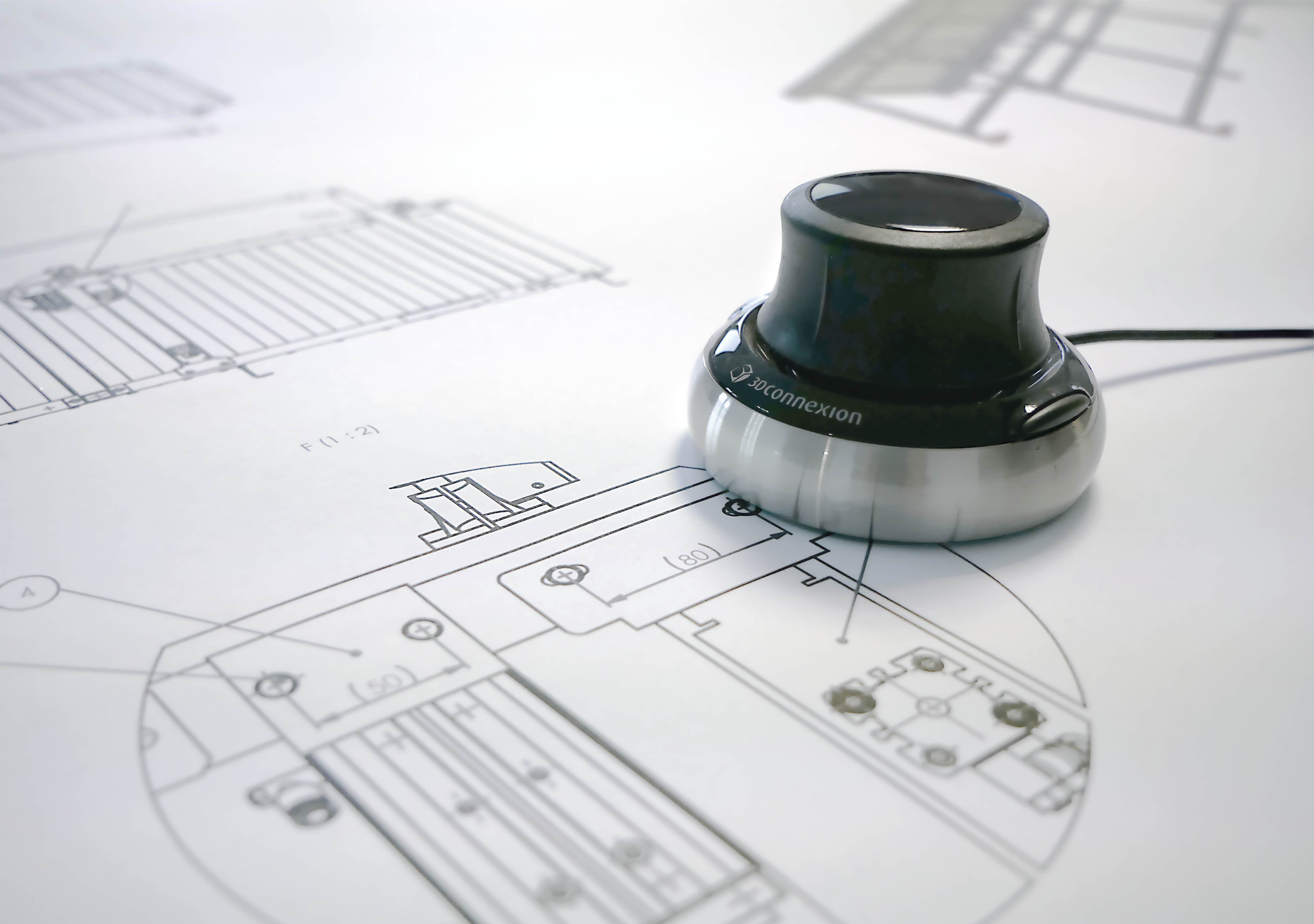

In the next step, our specialists in the project management and design departments are your contacts for planning and developing your plant concept.

Have you decided in favour of ASA AUTOMATION? Then it's time for the next phase.

Have you decided in favour of ASA AUTOMATION? Then it's time for the next phase.

Based on your specifications, our project management team will work with the design department to draw up the requirements specification and schedule. The details and milestones are agreed with you in a kick-off meeting.

Our design specialists, consisting of electrical, mechanical and technical engineers, are responsible for the implementation in production-ready design drawings (CAD), parts lists, pneumatic and electrical plans.

Comprehensive documentation and operating instructions are a matter of course for us.

SOFTWARE PROGRAMMING

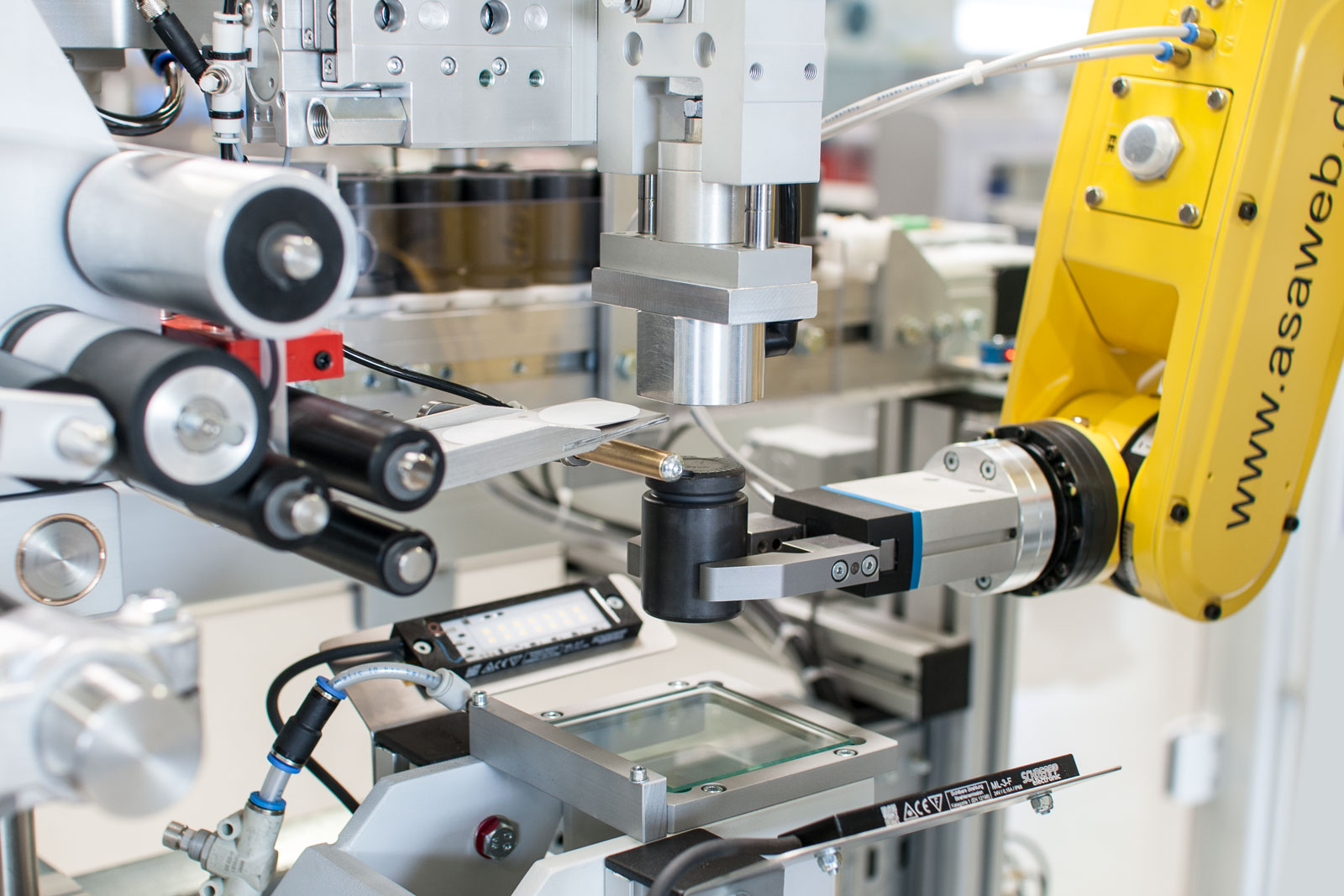

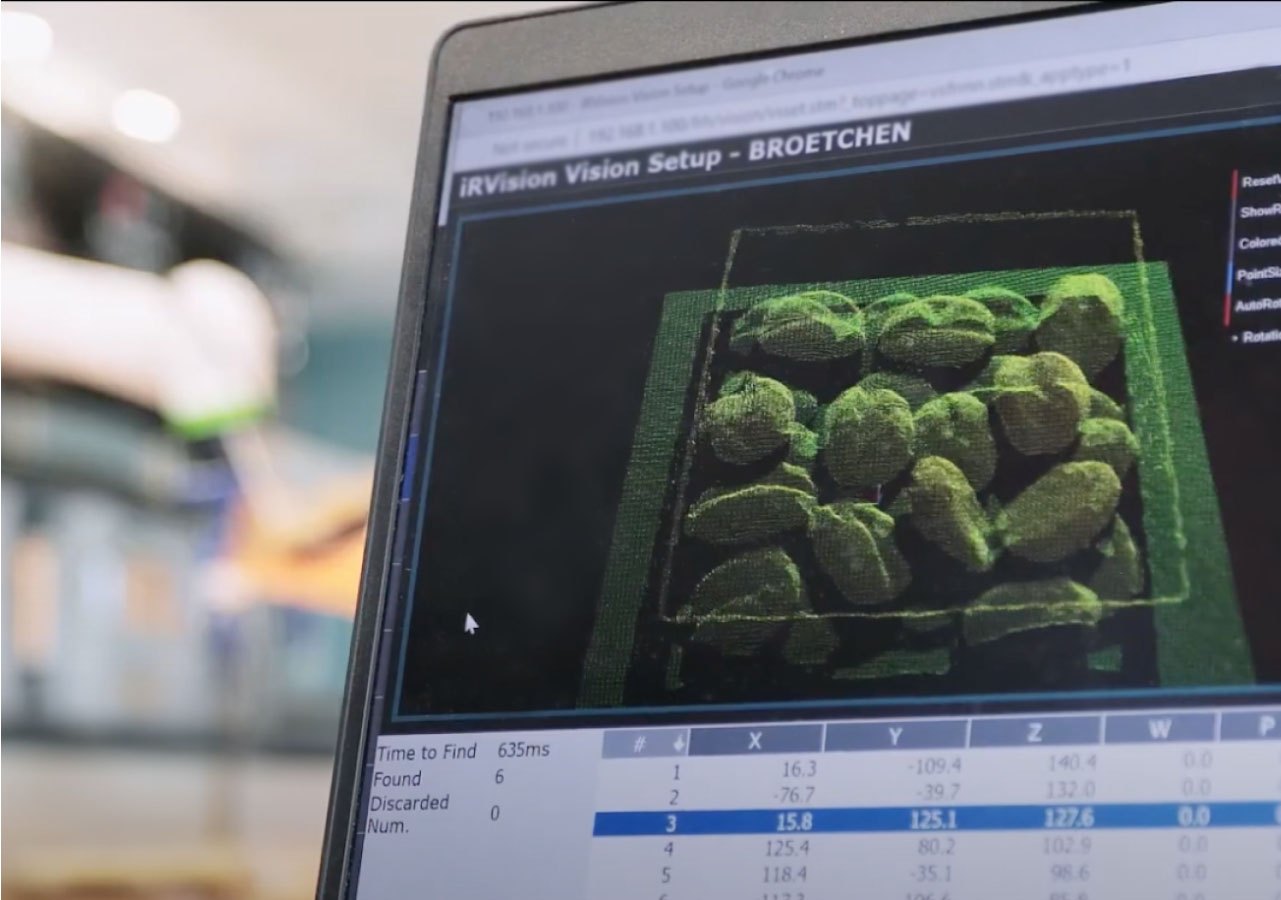

In the field of software, our specialists take care of PLC and robot programming as well as vision system integration for a wide range of automation applications.

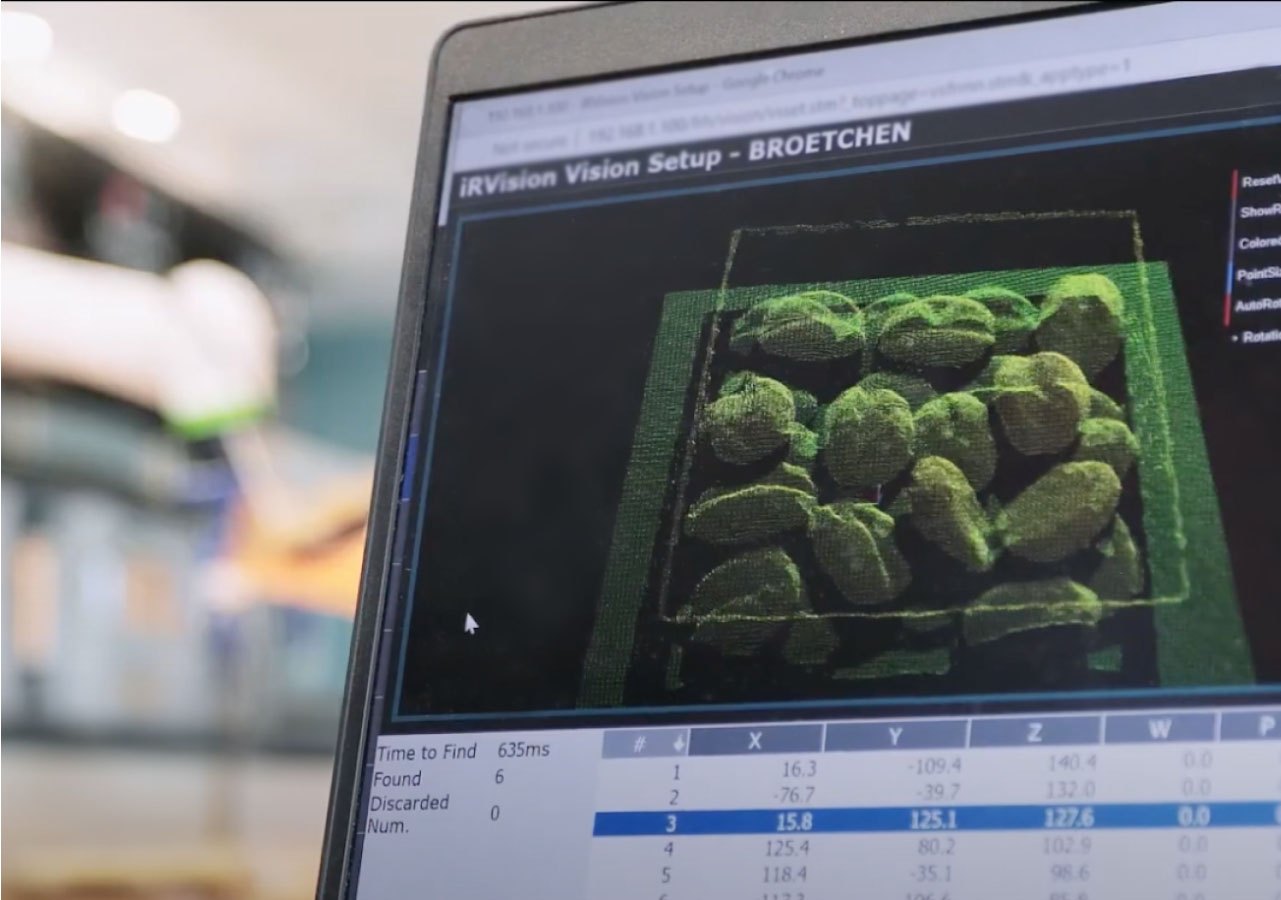

Today's consumers have very high expectations. A bread roll must not be too brown, a biscuit must have the right shape and a brake piston must be correctly assembled.

Today's consumers have very high expectations. A bread roll must not be too brown, a biscuit must have the right shape and a brake piston must be correctly assembled.

The tasks of vision systems (image processing programs) in this context are quality control, product sorting and position recognition.

The use of a vision system is particularly advantageous for robot-assisted gripping processes. For example, position deviations of a product are recognised by the image processing software after the image has been captured, if necessary with the aid of AI, and the optimum gripping coordinates are transmitted to the robot controller.

This interaction helps us to offer you a high degree of efficiency, availability and process reliability with our automation systems.

Our software specialists select the right vision system and the corresponding hardware and software components depending on your requirements.

A precise software concept is the centrepiece of a system.

A precise software concept is the centrepiece of a system.

The robot programming team ensures the precise control of your industrial robots and their targeted movements. It has extensive knowledge of different applications, requirements and robot manufacturers (e.g. ABB, Fanuc, KUKA and many more).

Our PLC programming team (programmable logic controller) ensures that your machines and systems run smoothly. It is proficient in the common programming languages Siemens S7 / TIA Portal, Beckhoff TwinCAT and many more.

Of course, the integration of servo technology is also part of our range of services.

PRODUCTION AND ASSEMBLY

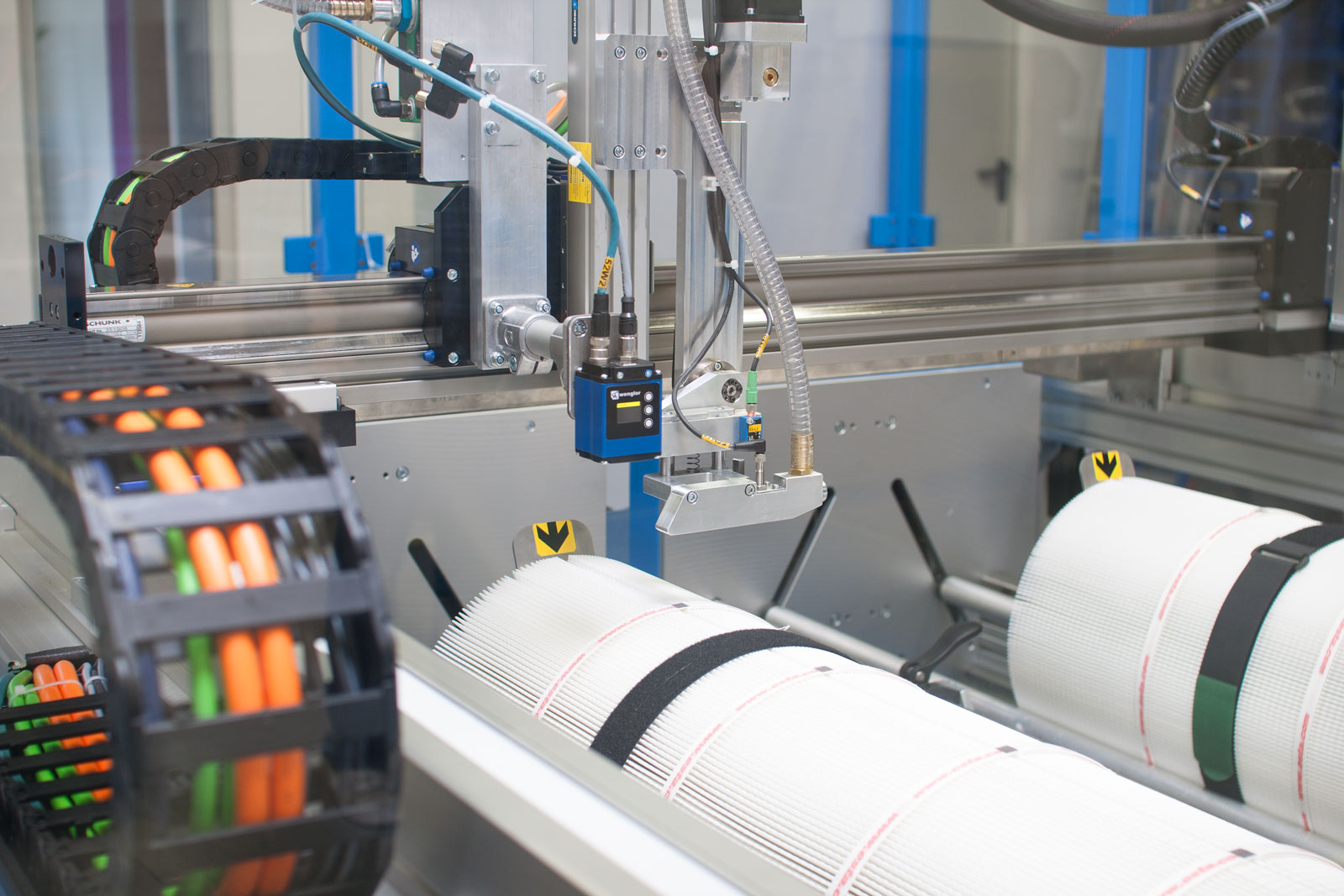

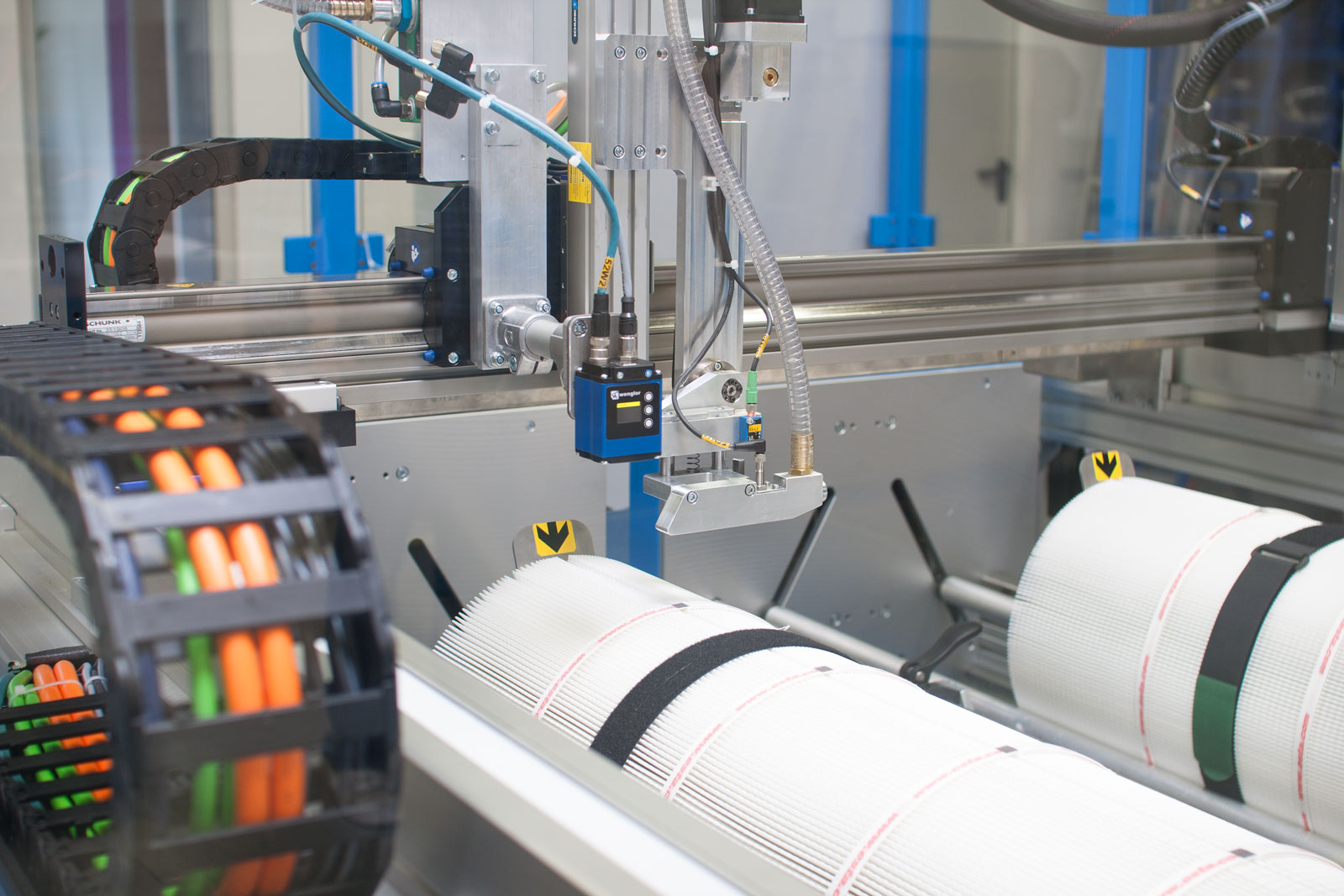

In the production and assembly departments, our specialists take care of the production of individual components and their assembly into modules, system parts and even complete systems.

That doesn't always have to be bad!

With our in-house production, which includes an electrical, turning and milling department as well as welding and assembly, ASA Automation has a vertical range of manufacture of almost 100%.

That doesn't always have to be bad!

With our in-house production, which includes an electrical, turning and milling department as well as welding and assembly, ASA Automation has a vertical range of manufacture of almost 100%.

This enables us to ensure fast response times and shorter production times in the manufacture of components and spare parts.

In-house production also means seamless quality control of the entire manufacturing process, ensuring that all guidelines and procedures are properly implemented.

Short distances ensure that our assembly team is quickly supplied with the required components. This is a particular advantage when repairs are needed at short notice.

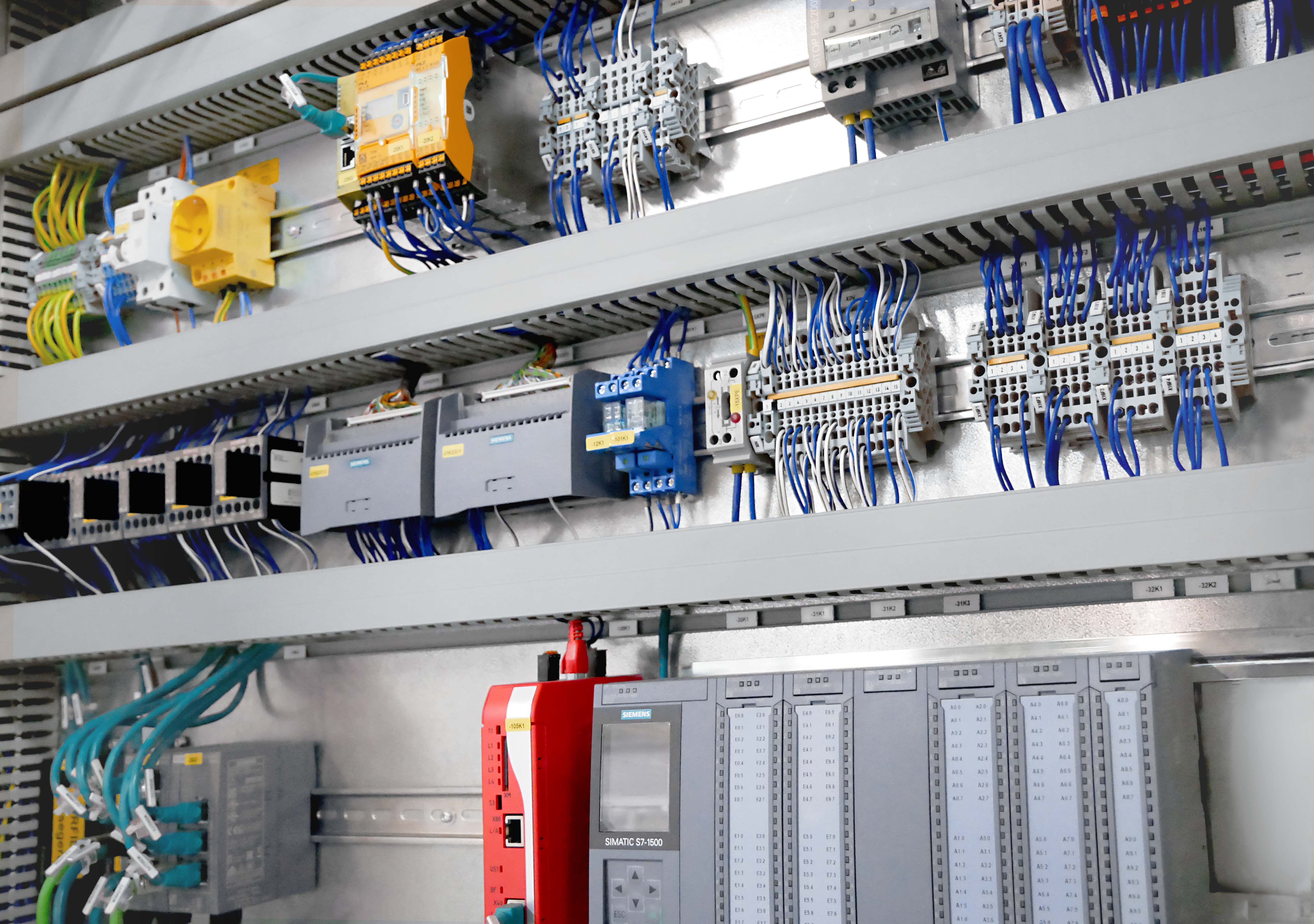

Admittedly, alongside robots, control cabinets are visually rather unspectacular elements of a system. However, their importance for power supply, control and data connection should not be underestimated.

Admittedly, alongside robots, control cabinets are visually rather unspectacular elements of a system. However, their importance for power supply, control and data connection should not be underestimated.

We plan (EPlan), build and customise control cabinets for industrial machines and systems according to individual customer wishes and technical requirements. This is done in compliance with all current national and international standards.

On-site installation and cabling of machines and systems are naturally also part of our scope of services. We are also happy to take on conversions or system expansions.

Commissioning and training

In the final phase, of commissioning, our specialists test the future operation of your system and then train your operating and maintenance personnel.

Now it's almost done! The factory acceptance of your system has been successfully completed. Now all that remains to be done is the installation, commissioning and familiarisation at your site.

Now it's almost done! The factory acceptance of your system has been successfully completed. Now all that remains to be done is the installation, commissioning and familiarisation at your site.

To begin with, our programmers will test all the cabling, sensors and safety technology of your system as well as the interfaces to integrated machines and system components. We then start commissioning your system. We test the future operation with workpieces.

If the system runs smoothly, we start with the last step for the time being and train your operating and maintenance personnel to ensure smooth handling.

Of course, we are also happy to continue to support you with our comprehensive range of services.